Screaming Circuits got its start back in 2003 with the intent of making prototype PCB assembly much easier, faster and available on the Internet. The world of electronics was a lot different back then. Surface mount technology (SMT) was far from new, but it was just then taking the reigns as the primary manufacturing technology and the SMT component sizes were getting too small for hand assembly.

Since that time, folks have discovered that our process works for more than just prototypes, which lead to our Short-Run and Choice-Production service offerings. Still, though, prototype PCB assembly is in our blood. But saying that it is in our blood doesn’t answer the question: “What is the difference between prototype PCB assembly and other types of electronics manufacturing?”

Here’s the way we look at it. First, “PCB Assembly” is a term closely related to “Electronics Manufacturing”, but primarily describes the process of getting the parts soldered on the blank printed circuit board. “Electronics Manufacturing” describes a more in depth and longer-term manufacturing relationship including design help, supply chain management and post-built functional test. “PCB assembly” is a part of the electronics manufacturing process and “electronics manufacturing” is more than just PCB assembly.

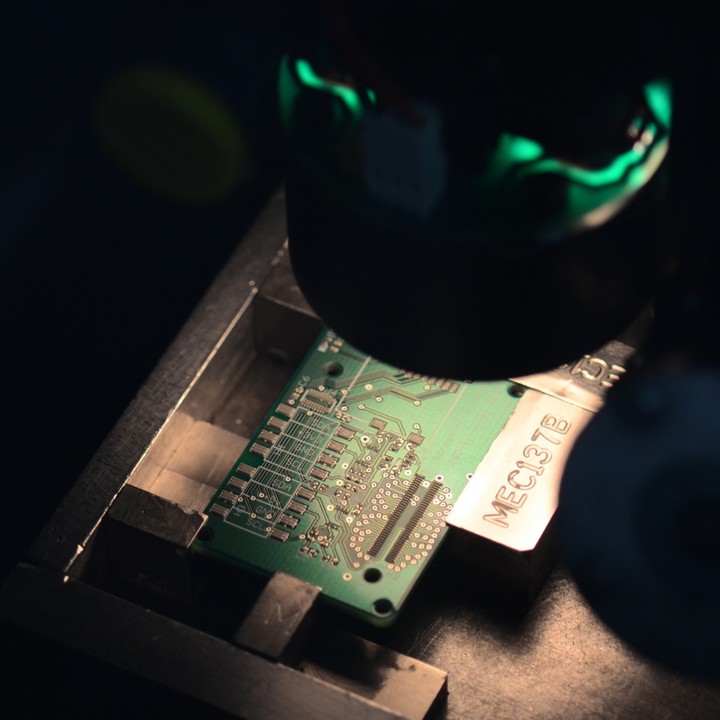

Quick turn came about due to the challenges faced when trying to get a small run of five or ten prototype units built on an assembly line normally used for runs in the thousands or tens of thousands. It can be a long, arduous and expensive process to change jobs out on a high-speed pick and place (PNP) assembly line. When we started, prototypes, though absolutely necessary for every electronic product, were often thought of as a bother rather than as an important part of the design and manufacturing cycle. Trying to get a set of prototypes built might take weeks or more despite the fact that the machine time might only be 30 minutes.

Prototypes are needed to validate that a design works, to make sure that it can be reliably manufactured and to use for firmware development prior to product launch. Two or three board spins (“spin” meaning to build, find and fix bugs, and rebuild) are not uncommon and if each of those spins takes you three weeks to build, your market window can easily end up in serious jeopardy.

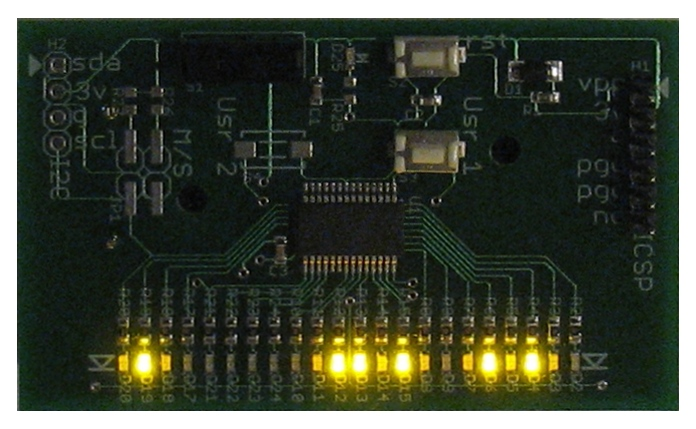

That’s where “prototype PCB assembly” came in, as well as “quick turn PCB assembly.” In 2003, we purchased one of the few types of PNP machines that were optimized for a quick change over. We designed and patented a system to allow the machines to use cut strips, like Digi Key sold. We built a simple online quote and order system and opened for quick turn PCB prototype assembly.

As it turns out, low volume and quick turn are needed for more than just prototypes. We found that quite a lot of custom machinery and research folks needed the same low volume service but had the same problems getting ten finished product boards built as did a design engineer who needed ten prototypes. Because of the quick turn and easy small volume capability, we have built circuit boards for underwater research projects, we’ve built a few that are as of this writing, out on the planet Mars, and for just about any application you can imagine that falls in between.

Finally, the “on-demand” term that you might hear us throwing around came about when folks started needing larger volumes, but time or circumstances didn’t allow for long-term forecasting. A good example would be a crowd funded product that sold 2,000 during the funding period. That small business owner clearly needed a few prototypes built and at least 2,000 finished products. However, anyone who has been involved in a crowd funded project knows that pre-selling a few thousand boards that then need to be built quickly, does not mean that there will be a steady stream of orders that would get the attention of a high-volume manufacturer.

On-demand electronics manufacturing just means that we don’t care if you need one unit, or 1,000 and never any more after that. On demand manufactures build what you need, when you need it, without any requirement for a long-term commitment. That can be pretty helpful in and fast moving or uncertain economic environment.

Now, if you have any need for PCB assembly, prototype or otherwise, hop over to our quote page and see how easy it is. If you don’t have that need, just keep reading the rest of our blog articles.

Duane Benson

Serious jeopardy is likely not as fun as final jeopardy.