While supply chain and labor shortages may get much of the attention these days, the world of design is not all that different than it was a few years ago. We still have to give focus to things like design performance and cost reduction.

Cost reduction is especially critical these days. No one is happy with the inflation all of us have been experiencing lately, but some companies are better able to tolerate cost increases then others. If said money is in short supply, there are some things you can do with your project that will help to soften the effects of inflation.

First, time is money. It’s an old adage, but a very relevant one. No matter where you are having your electronics built, shorter lead times will cost you more. Accepting longer lead times will have the largest impact on the assembly cost.

Watch this video for this and other design tips to help you reduce your project costs.

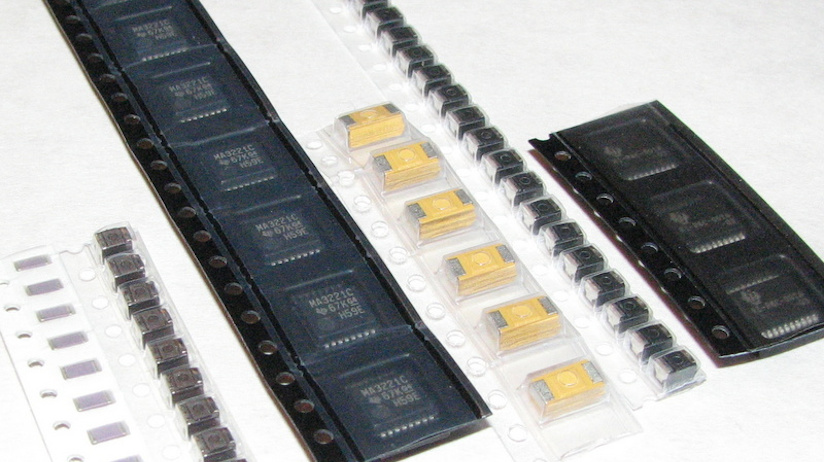

And, don’t forget to pay attention to your Bill of Materials (BOM). As I said above, availability tends to get most of the attention today, but component selection can greatly affect your project cost. Smaller parts tend to cost less these days and are more likely to be available. Sometimes picking a “close but not exact” alternate, along with a small amount of redesign can result in a less expensive BOM.

The Bill of Materials’ Role in Cost Reduction

If you can reduce the number of different parts (reduce the number of BOM line items) you can save money too. For example, if you need a few 6-volt .01uf capacitors and a few 16-volt .01uf caps, you can probably get by with all 16-volt parts. You may be able to combine some resistor values in non-critical design sections too.

Spend the time for a second or third look and you may be surprised how much cost you can cut out. Then once you’re all set, head over to our PCB Assembly quote page and see what it takes to have us buy and build your boards.

Duane Benson