With surface mount parts being so thoroughly entrenched, one might think that thru-hole parts and thru-hole soldering are no longer a part of the electronics manufacturing scene. While it is true that the vast majority of parts today are surface mount, there are still plenty enough thru-hole parts being used. Enough, in fact, that Screaming Circuits offers three different methods of soldering: hand solder, selective solder, and wave solder.

We still hand solder thru-hole components when there are only a few boards. We will often use our selective solder machine when there are a mix of thru-hole and surface mount parts but not enough boards to justify creation of a wave solder fixture.

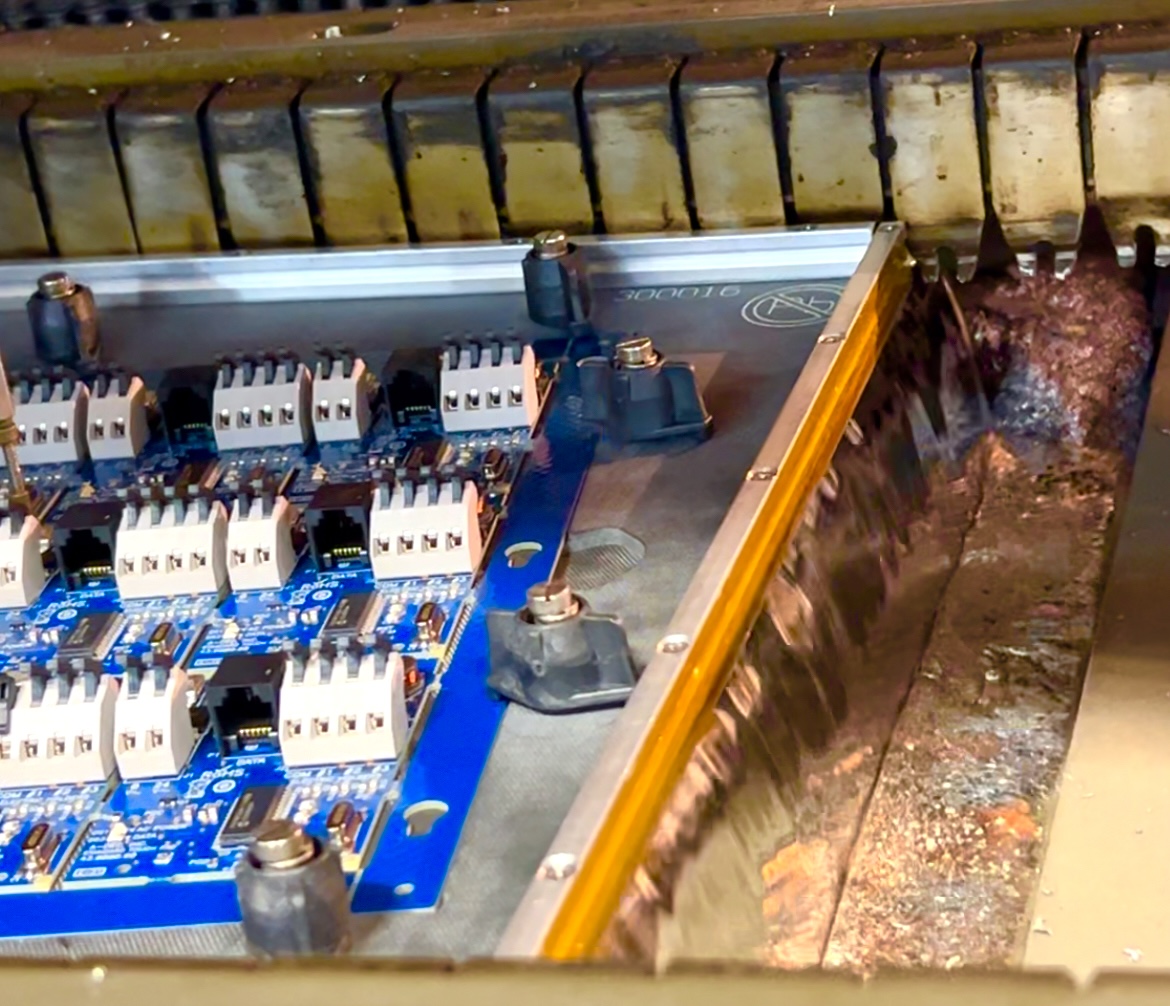

Wave soldering gets the “go” when we have a lot of boards, especially when there will be multiple runs of the board, such that it’s more efficient to create a wave palette.

Though wave soldering has been around for decades, it still serves the industry well – and it’s fascinating to watch. If you’ve got thru-hole or surface mount components that need to be assembled, jump to our PCB Assembly quote page and see what it will take to have us build them for you.

Screaming Circuits